YKİ-04 MAINTENANCE TROLLEYS

- Home

- MAINTENANCE TROLLEYS

- YKİ-04 MAINTENANCE TROLLEYS

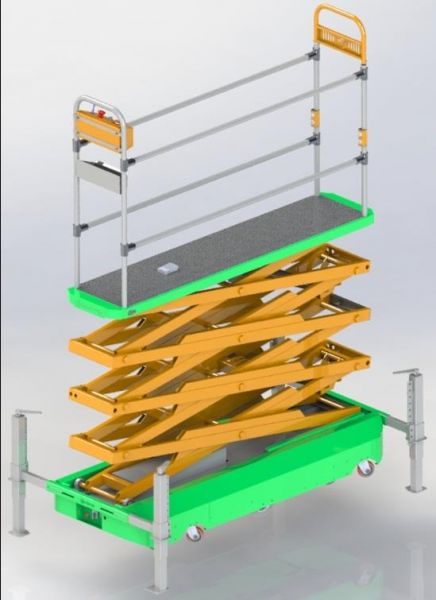

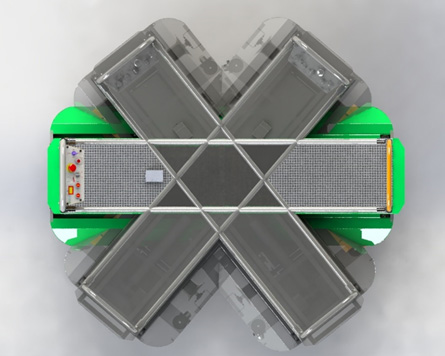

YKİ-04 MAINTENANCE TROLLEYS

The maximum lifting height of the YKI-04 greenhouse maintenance trolleys is 4,5 meters. The YKI-04 model allows the user to work comfortably at 6.5-7 meters.

It is located in a different position with the power it receives from the YKI-04 dual engine. The joystick on it allows the user to direct the machine without having to descend through the machine at the end of the rail. The machine can be conveniently guided on intermediate roads via the platform with a joystick or with decks under the back door.

With METALMAK greenhouse maintenance trolleys, you can quickly handle your technical work without disrupting it.

Get Offer

Platform lifting height 4500 mm.

Platform lifting capacity 240 kg.

The maximum speed is 48 Meters / minute on the rail.

The machine has a battery of 2x105 amps.

Easier movement thanks to 2 separate motion engines located on the machine.

The platform is covered with non-slip patterned aluminum sheet on steel material.

The platform has a durable motion pedal with an aluminum body.

The driver in the machine has a braking feature on it, and as soon as the user pulls his foot from the pedal, a soft braking feature is activated.

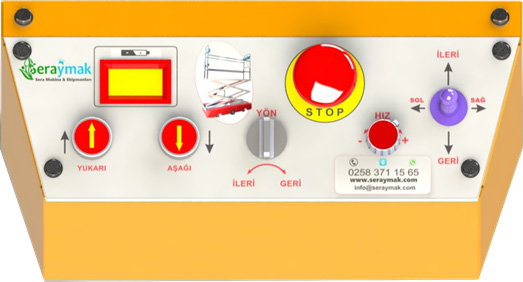

There are up-down buttons, forward-backward direction determination button, stepless speed adjustment pot, emergency stop button, voltage indicator and joystick on the control panel.

The charger is placed in a convenient place on the machine. Thanks to the indicator light on the charger, you can see the charging status of the machine. When the charging lamp changes from red to green, it means that the charging process is complete.

Our chargers have the ability to cut off electricity as soon as the batteries become fully charged, preventing the negative effects of overcharging.

The YKI-04 also has a sub-control panel. On the lower control panel there is a main switch, up-down movement buttons, a charging socket with a switch.

If the machine is forced, the card is protected and the card is prevented from failing. With 2 reset keys on the machine, you can easily activate each card again.

YKI-04 model protruding edges are free of sharp corners and designed to not damage plants during operation with a narrowed width according to its peers.

There is a self-closing security door on the Model.

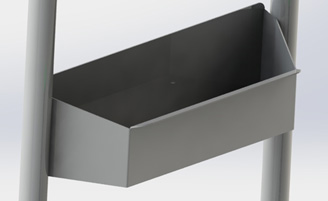

A storage pocket is placed on the platform so that users can put their necessary materials.

The YKI-04 model has no space between the rail wheel and the tire wheel due to its different wheel structure. Due to the combined wheel system, rope, etc. as a result of the entanglement of substances, the disadvantages that will be experienced, such as the restriction of wheel movement and friction on the track, were prevented.

In the YKI-04 model, all of the wheels are hidden inside the chassis. Thanks to hidden wheels, unwanted work accidents (crushing feet, hitting around, etc.) cause status is reduced.

The YKI-04 model has a total of 6 rail wheels, the front part, the middle part and the rear part.

This model has the ability to automatically rotate where it is located using the joystick or rear buttons without the need for any lifting lever.

Machine motion buttons;

| MODEL | YKİ-04 |

| ENERGY SUPPLY | BATTERY / 2 X 12 V-105 A |

| HYDRAULIC ENGINE | 800 W DC X 1 |

| MOVEMENT ENGİNE | 400 W DC X 1 |

| CHARGER(INTERNAL) | AVAILABLE |

| ENERGY REQUIRED FOR CHARGING | 220 VOLT / 50 Hz |

| CHARGING CABLE | AVAILABLE |

| WORKING TIME (Depends on Usage) | 2 DAY |

| MAXIMUM SPEED OF CONCRETE FLOOR | 105 m / dak |

| MAXIMUM SPEED ON RAIL | 48 m / dak |

| MAXIMUM LIFTING HEIGHT | 4500 mm |

| PLATFORM BOARDING HEIGHT | 818 mm |

| MACHINE WEIGHT | 540 kg |

| MAXIMUM LIFTING CAPACITY | 240 kg |

| STANDARD WORKING RAIL PIPE DIAMETER (SPECIAL PRODUCTION IS MADE FOR YOU IN DIFFERENT RAIL SIZES.) |

51 mm |

| STANDARD WORKING RAIL OUTER-OUTER DIMENSION (SPECIAL PRODUCTION IS MADE FOR YOU IN DIFFERENT RAIL SIZES.) |

600 mm |

| TRANSFER TO SIDE RAIL | AUTO (JOYSTICK) |

| MACHINE BACK MOTION BUTTONS; (FORWARD-BACKWARD-RIGHT-LEFT) |

AVAILABLE |

| SPEED MODE | AYARLANABLİR |

| CHARGING INDICATOR | AVAILABLE |

| USER ITEM BOX | AVAILABLE |

| SECURITY GATE | AVAILABLE |

| LED HEADLIGHT | OPSİYONEL |

| PAINT | ELECTROSTATIC POWDER COATING |

| GUARANTEE | 1 YEAR |

Similar Products

Similar Products

Contact us

"Always the Best"

Cumartesi: 08.00 - 16.00

Pazar: Kapalı